The Oil System Is

The oil system is. Most cars use a wet sump system. The purpose of a lube oil system is to continuously provide cool clean oil to the bearings and gear if applicable at the proper pressure temperature and flow rate. The more you say it the weirder it sounds.

Oil therefore faces a perfect storm from both above and below. Also this light can come on if the oil pressure of the engine drops. The oil pump is a highly critical part of the engine - if an oil pump stops working it will lead to expensive engine failure 100 of the time.

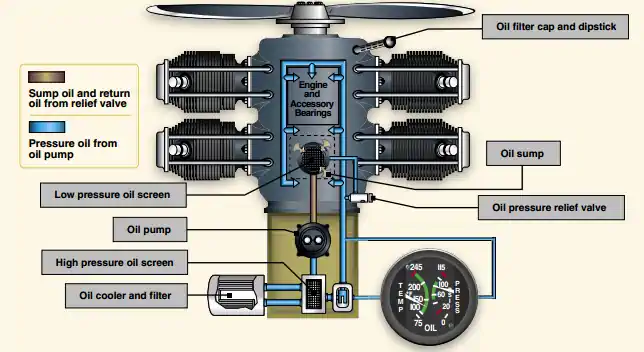

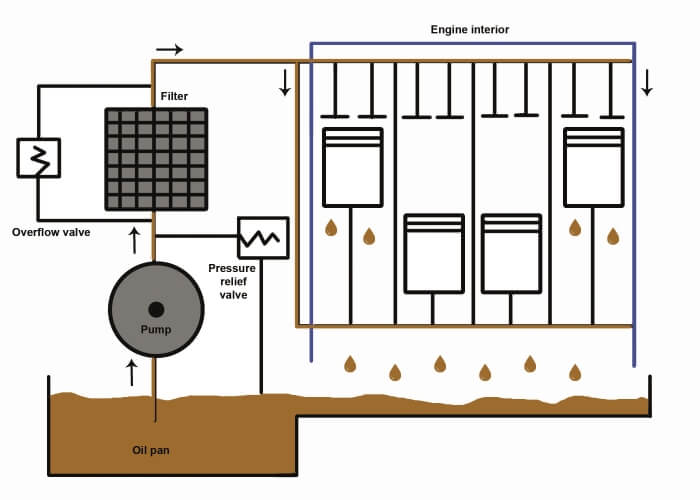

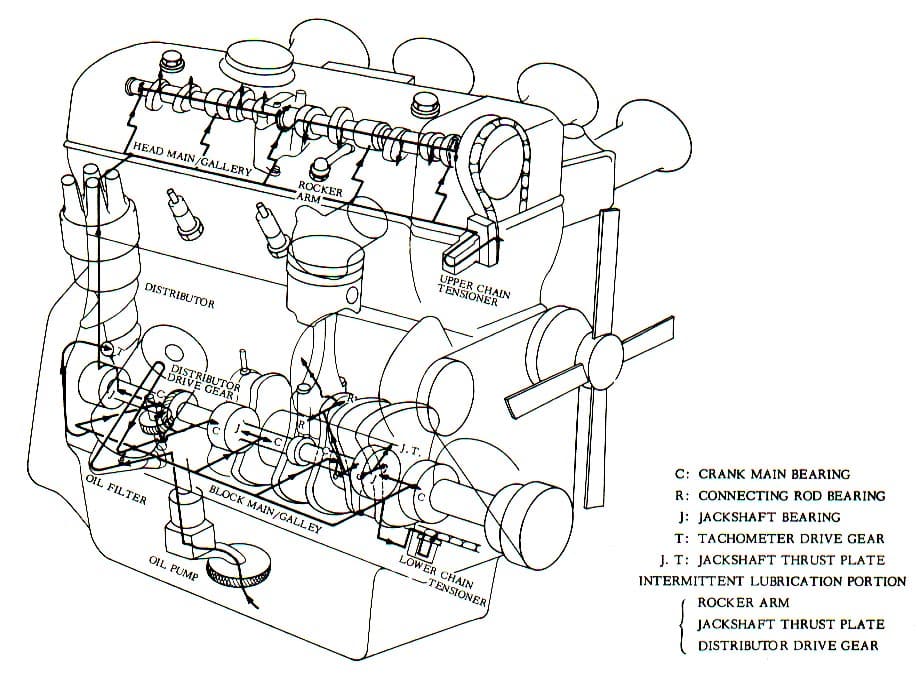

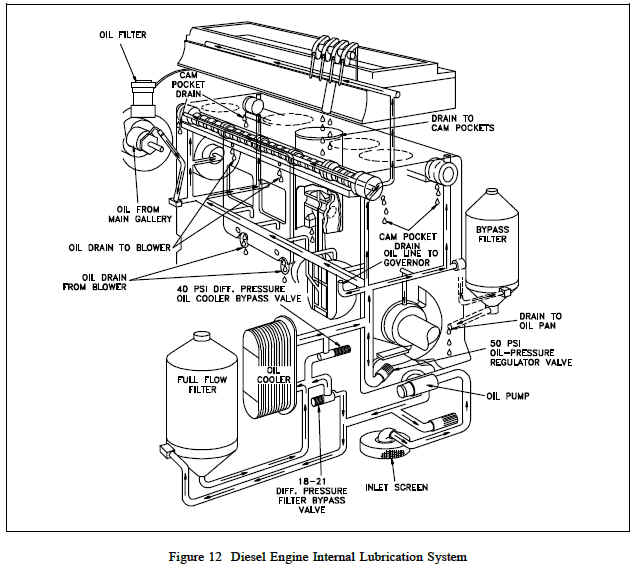

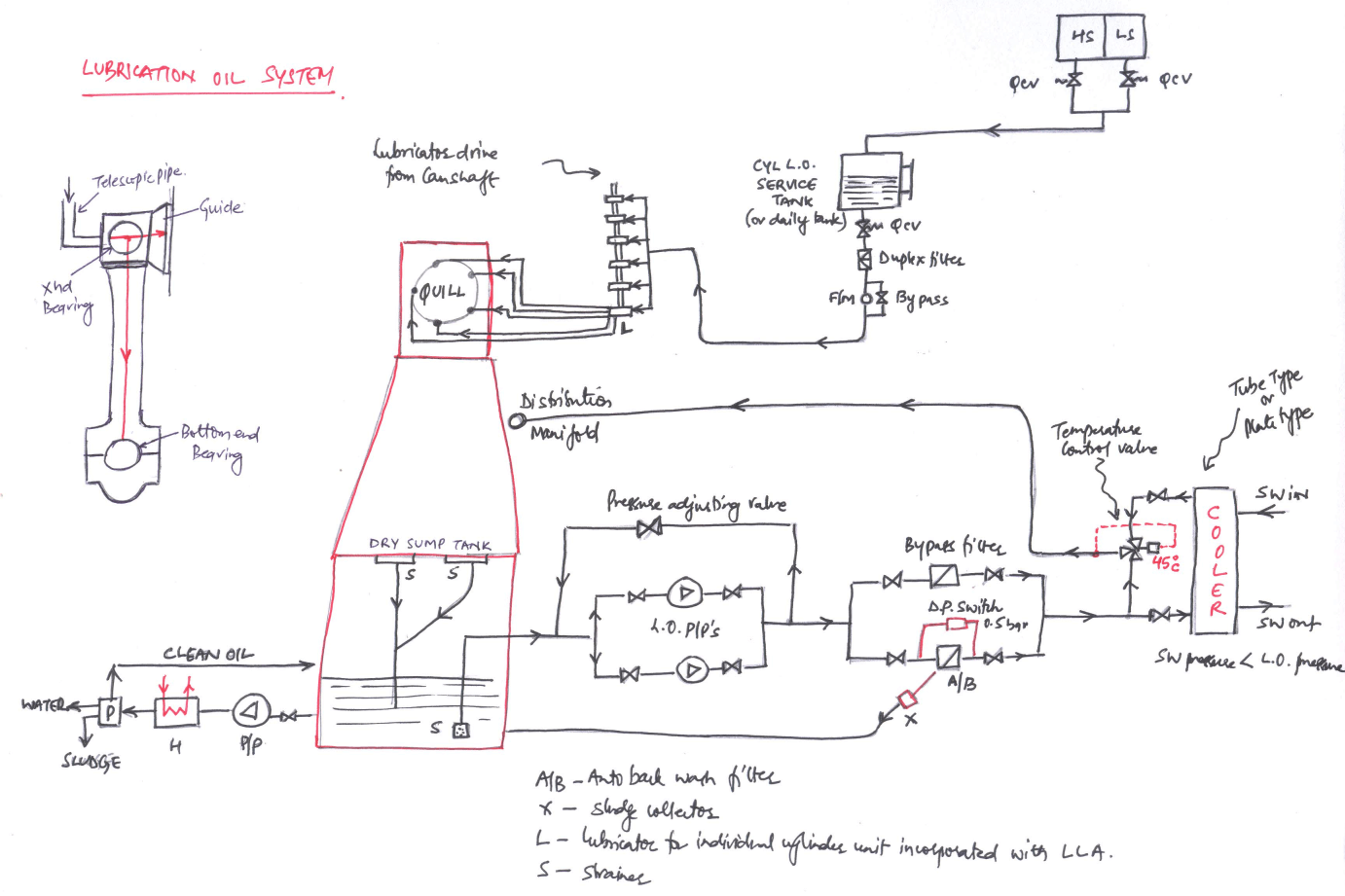

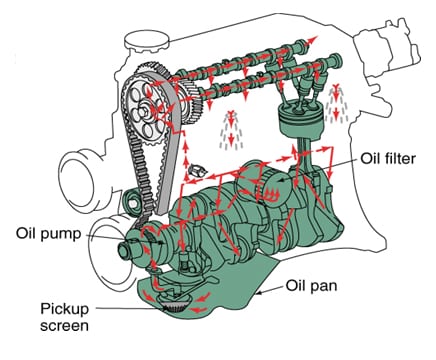

It sucks oil up from the oil pan and forces it around oilways in the engine before the oil drops back into the sump and is recirculated. For oil systems insulated systems that maintain temperatures above the hydrate formation temperature during steady-state allow hydrates to be controlled with a minimum usage of glycol or methanol. Oil pump provides a continuous supply of oil at sufficient pressure and quantity to provide adequate lubrication to the entire engine.

The normal case is that the lubricating oil stays in the engine without replacement. Pressure pump 4 forces the de-gassed and cooled oil 5 back to the. If refrigerant oil did the same thingthat is if it remained in the.

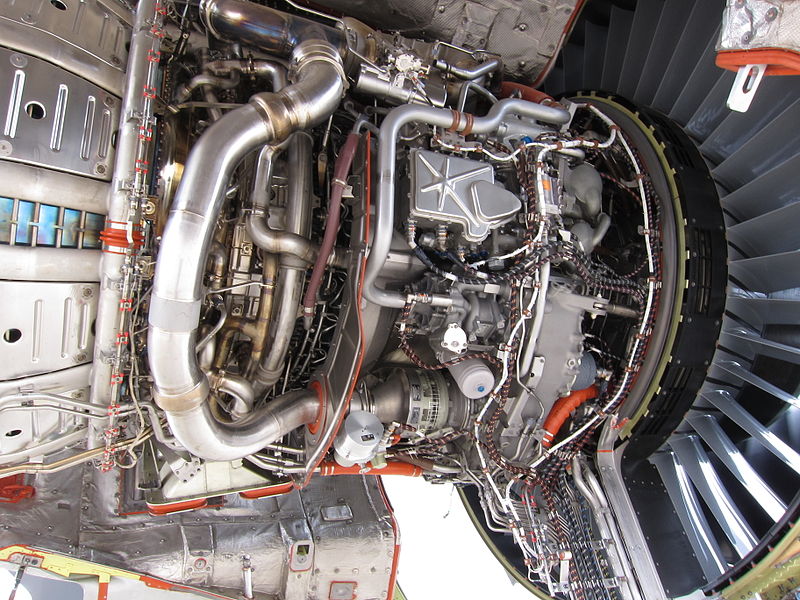

The system oil in large medium and low speed diesel engines is intended to be in use for a long time. Consumption during operation and loss of oil in the cleaning system is compensated for by the topping up the volume with new oil. Oil a hydraulic fluid is one of the vital components of the IDG.

An oil Collar may be used to carry oil from reservoir to j ournal which are rotating at high speed so that ri ngs and chains would slip. There are mainly three types of Lubrication System. Special formulations of oil are required to lubricate the internal components of a compressor adding to the expense of manufacturing and operating cooling equipment while raising environmental issues such as disposal of waste oil and ozone depletion that contributes to global.

It is Accessible in the Engine Nacelle. Only the loss of oil eg.

Oil is used in refrigeration systems to lubricate compressor bearings and other moving parts.

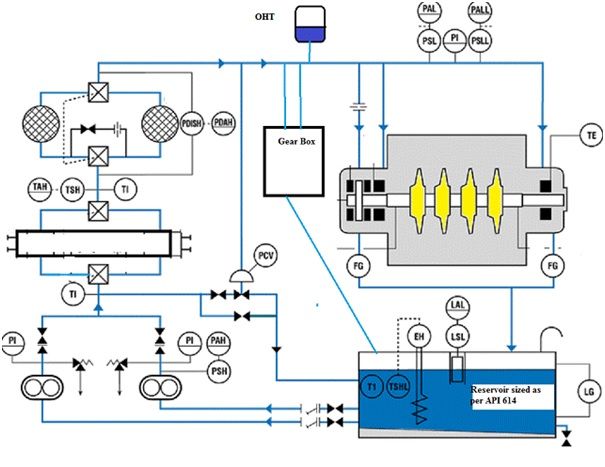

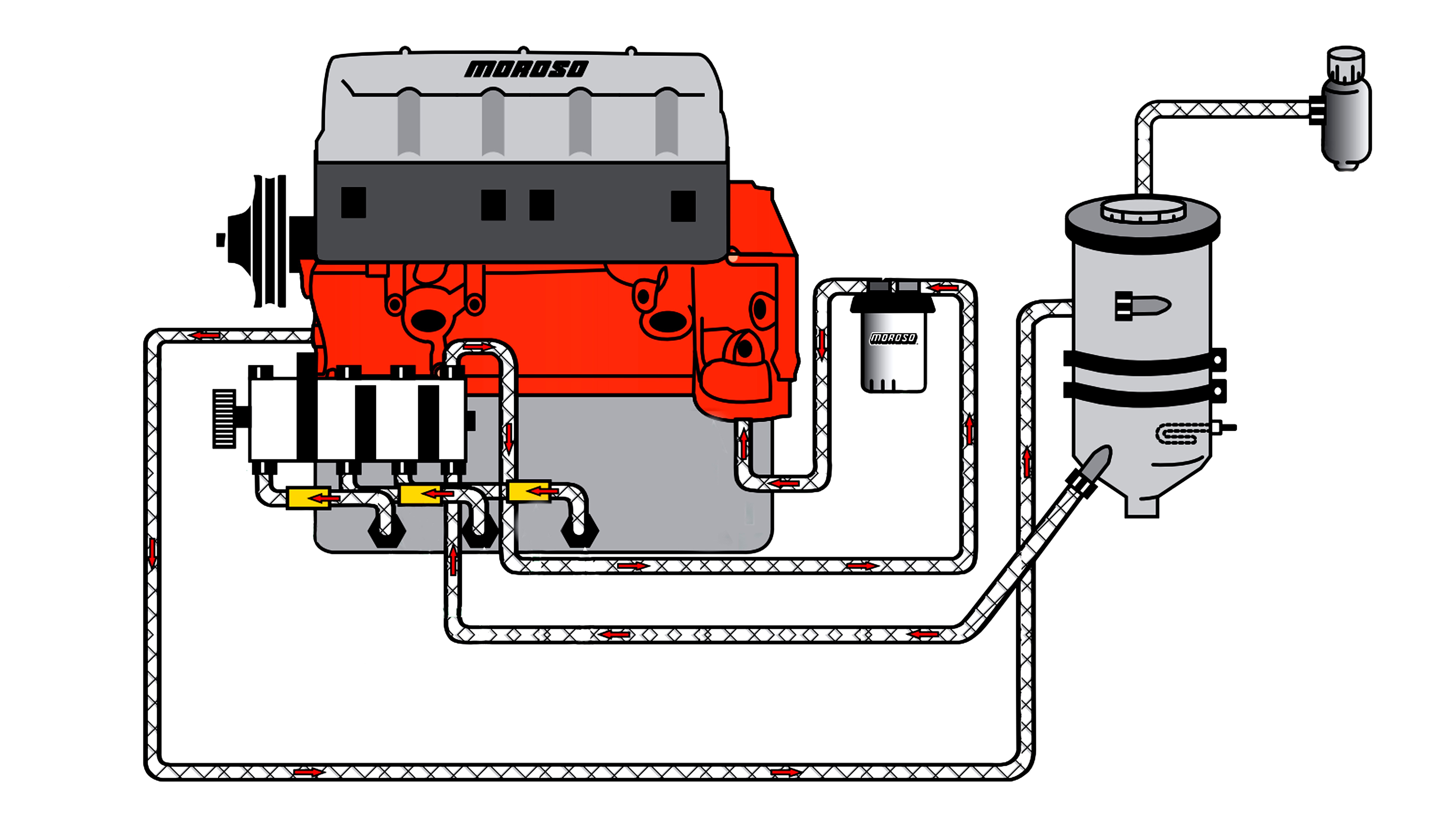

The oil circuit is divided into power oil control oil and lubricating oil. It sucks oil up from the oil pan and forces it around oilways in the engine before the oil drops back into the sump and is recirculated. Oil therefore faces a perfect storm from both above and below. When the system has calculated that oil life has been diminished it indicates that an oil change is necessary. Remember the Oil Life display must be reset after each oil change. The oil pump is the heart of the lubrication system. Oil is used for cooling and lubrication and is also used to by the CSD to regulate the rotation speed of the generator mechanically. Change the oil as soon as possible within the next 1 000 km 600 mi. Schematic diagram of a basic dry-sump engine lubrication system.

The purpose of a lube oil system is to continuously provide cool clean oil to the bearings and gear if applicable at the proper pressure temperature and flow rate. The normal case is that the lubricating oil stays in the engine without replacement. The properties of the oil selected must be suitable for this purpose. The oil collects in sump 1 is withdrawn continuously by scavenge pump 2 and travels to the oil tank 3 where gases entrained in the oil separate and the oil cools. Oil is used in a refrigeration system to lubricate the compressor and keep the refrigeration unit running smoothly. When the oil life is low or near to 0 the messaging system will show you an oil change due message. For oil systems insulated systems that maintain temperatures above the hydrate formation temperature during steady-state allow hydrates to be controlled with a minimum usage of glycol or methanol.

Post a Comment for "The Oil System Is"